All Services

Opening Hours

- Mon - Sat: 10.00 AM - 4.00 PM

- Sun: 09.00 AM - 4.00 PM

- Friday: Closed

- Emergency: 24 hours

Loading

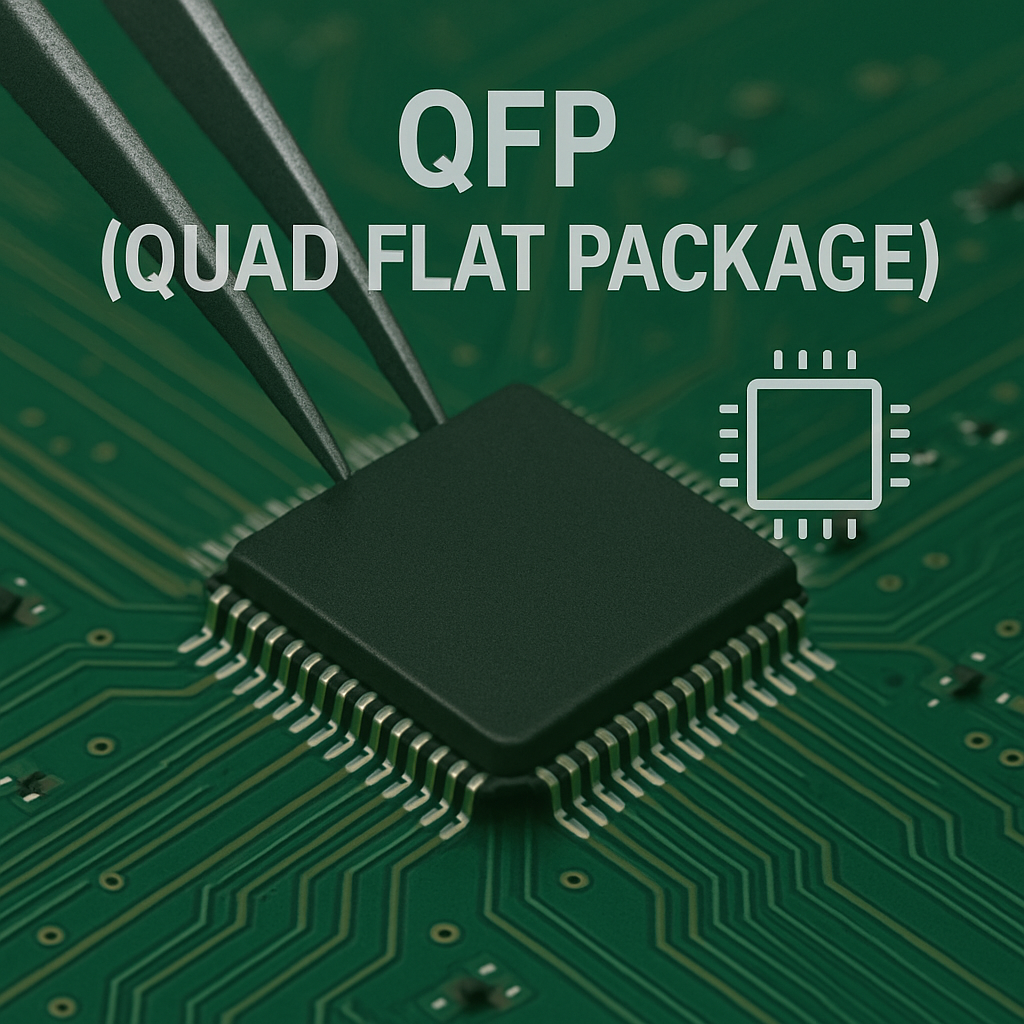

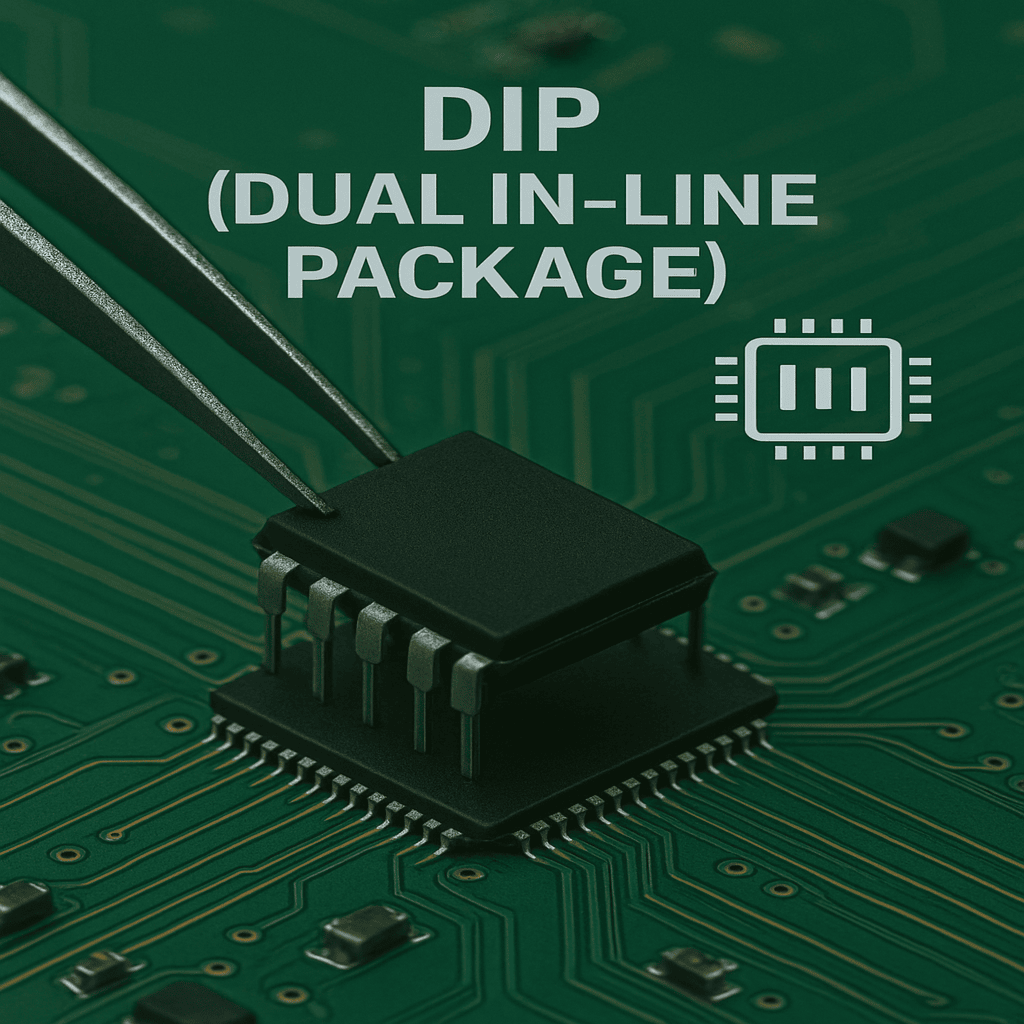

Integrated Circuit (IC) packaging is the process of enclosing a semiconductor chip in a protective housing that supports its operation and integration into larger electronic systems. It not only shields the chip from environmental factors like moisture and physical damage but also enables it to interface with the outside world through electrical connections and thermal management.

As semiconductor technologies evolve and shrink in size, packaging plays an increasingly critical role in maintaining the chip's reliability, performance, and longevity.

We provide customized IC packaging services tailored to your product’s requirements. Our capabilities include:

Our team ensures your devices are ready for real-world deployment by focusing on functionality, durability, and manufacturability.

Our IC packaging solutions are designed to support a variety of industries, including:

Choosing us as your IC packaging partner means gaining:

We focus on building solutions that fit your business goals — with precision, speed, and dependability.

Our packaging process is comprehensive and detail-oriented, ensuring your chip performs as expected from design to deployment:

Find answers to the most asked queries on IC packaging, from protective enclosures to thermal solutions in modern semiconductor design.