All Services

Opening Hours

- Mon - Sat: 10.00 AM - 4.00 PM

- Sun: 09.00 AM - 4.00 PM

- Friday: Closed

- Emergency: 24 hours

Loading

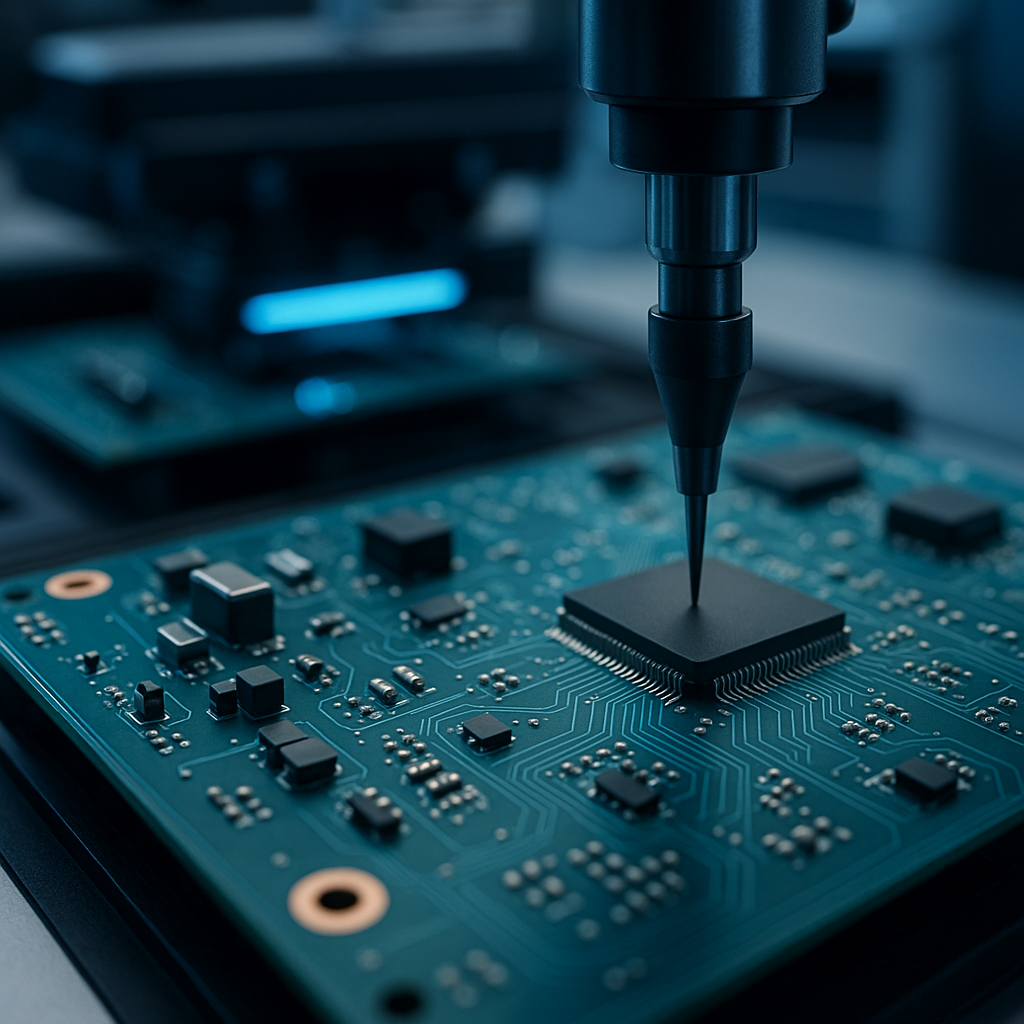

Semiconductor electronics manufacturing involves converting raw materials into complex, high-performance chips used across modern technologies. This highly specialized process requires precision tools, cleanroom environments, and advanced fabrication techniques to ensure consistent quality and efficiency.

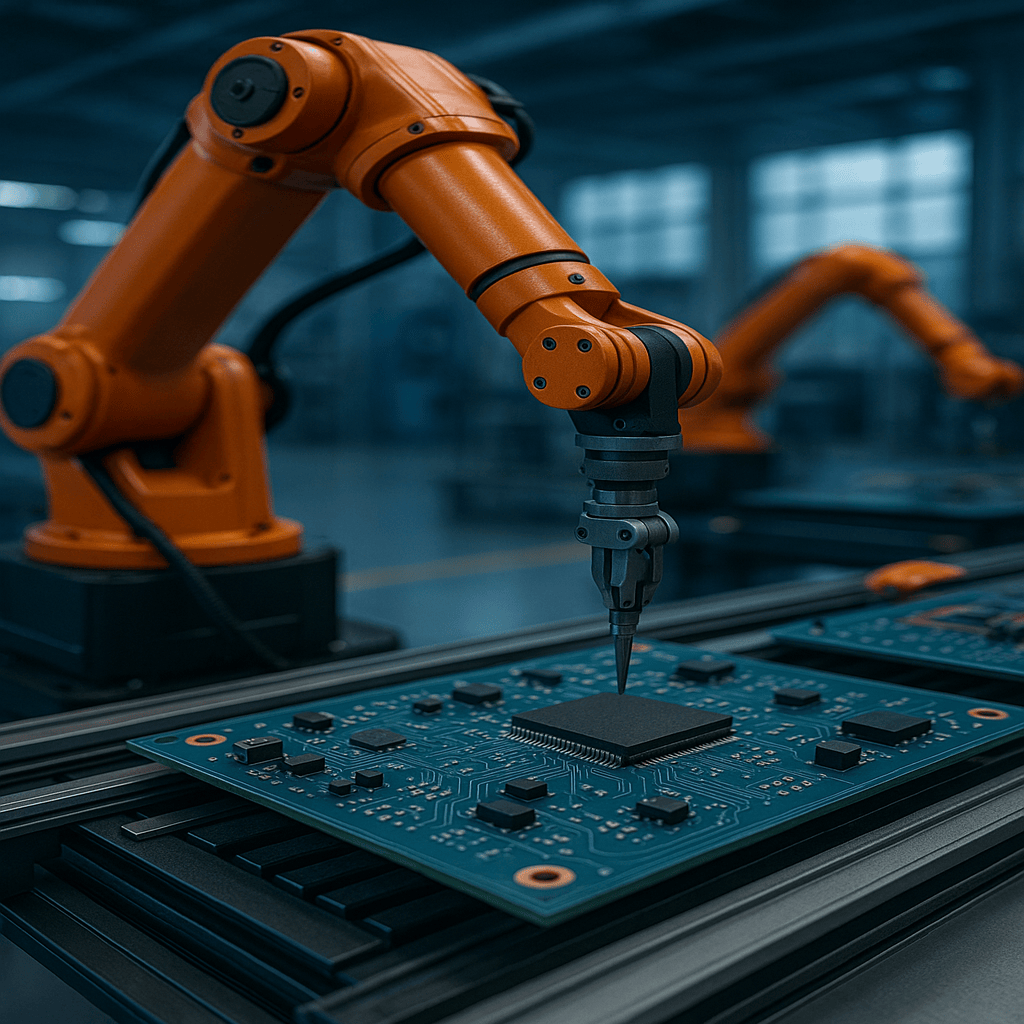

We deliver complete support across the semiconductor manufacturing lifecycle—from wafer processing to assembly, testing, and logistics. Our services are built around ensuring performance, reliability, and cost-effectiveness at every production stage.

Our semiconductor manufacturing solutions support a wide range of sectors including:

Choosing us means gaining a reliable manufacturing partner focused on quality, innovation, and delivery. Our commitment to precision, flexibility, and customer-centric collaboration allows us to adapt to evolving demands and deliver production-ready results, on time.

We follow a streamlined and transparent manufacturing process:

Find answers to the most frequently asked questions about our electronics manufacturing services. From design to delivery, we clarify the key steps in building innovative, reliable electronic products.